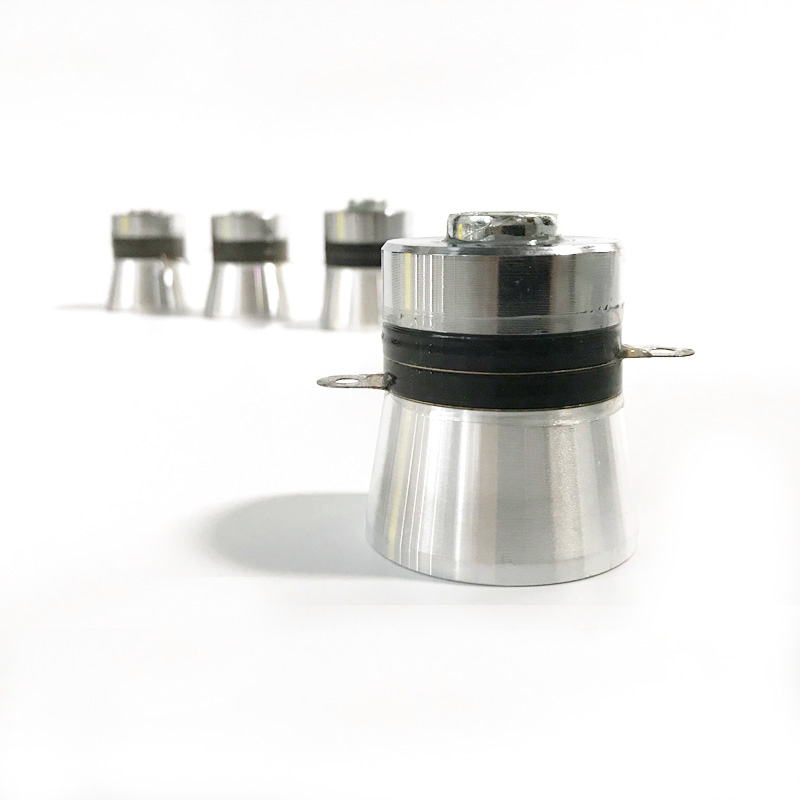

ultrasonic transducer for cleaning 28khz/40khz

ultrasonic transducer for cleaning 28khz/40khz 上一篇:ultrasonic welding transducer for plastic Metal 15khz/20khz

下一篇:没有了

Ultrasonic cleaning transducer has shown great superiority in ultrasonic cleaning machine.

Ultrasonic cleaning transducer, especially in the specialized and group production enterprises, has gradually replaced the traditional immersion cleaning, brushing, pressure washing, vibration cleaning and steam cleaning with ultrasonic cleaning machine. The high efficiency and high cleanliness of the ultrasonic cleaning machine are due to the penetrability and cavitation shock wave generated when the sound wave propagates in the medium. Therefore, it is easy to clean the parts with complex shape, inner cavity and fine space. The general process of oil removal, rust prevention and phosphating can be completed in two or three minutes under the effect of ultrasonic. Its speed can be several times to dozens of times higher than the traditional method, and the cleanliness can also reach high standards. This is more important in many occasions with high requirements for product surface quality and productivity The results that are difficult to achieve or irreplaceable by other methods are highlighted.

The advantages of ultrasonic cleaning transducer are summarized as follows:

(1) The cleaning speed is fast, the cleaning effect is good, the cleanliness is high, the workpiece cleanliness is consistent, and there is no damage to the workpiece surface.

(2) It is safe and reliable to clean deep holes, fine seams and concealed parts of workpieces without touching the cleaning liquid by hand.

(3) Save solvent, heat energy, workplace and labor.

(4) The cleaning precision is high, and it can clean the tiny dirt particles powerfully.

The ultrasonic cleaning transducer should be placed in a dry place, so as to prevent the ultrasonic vibrator from being damped and affecting the normal work. If the ultrasonic vibrator is damped, put it into the oven and set it to 100 ℃ for 2 hours or use the electric blower to remove the moisture until the resistance value is normal; if the ultrasonic vibrator is degummed, the output power of the ultrasonic power supply is normal after the ultrasonic vibrator is degummed, but the connection between the vibrator and the vibration surface is not good, If you work for a long time, you will burn out the vibrator. Generally, the ultrasonic vibrator degumming should be repaired or replaced by a professional ultrasonic manufacturer.

| Type | Length(mm) | Weight(g) | Frequency(KHz) |

Resonance Impedance (Ω) |

Static Capacity (pF)±10% |

Input Power(W) |

|

UCE-UT-20100 PZT-8 |

94 |

900 |

20 |

10-20 |

5200 |

100 |

|

UCE-UT-25100 PZT-4 |

77 |

710 |

25 |

10-20 |

6600 |

100 |

|

UCE-UT-28120 PZT-4 |

66 |

720 |

28 |

10-20 |

7800 |

120 |

|

UCE-UT-28100 PZT-8 |

66 |

625 |

28 |

10-20 |

5200 |

100 |

|

UCE-UT-28100 PZT-4 |

66 |

624 |

28 |

10-20 |

6600 |

100 |

|

UCE-UT-30100 PZT-8 |

61 |

555 |

30 |

10-20 |

5200 |

100 |

|

UCE-UT-2560 PZT-4 |

77 |

530 |

25 |

10-20 |

5400 |

60 |

|

UCE-UT-2860 PZT-8 |

68 |

470 |

28 |

10-20 |

3800 |

60 |

|

UCE-UT-2850 PZT-4 |

82 |

425 |

28 |

10-20 |

4100 |

50 |

|

UCE-UT-3360 PZT-8 |

58 |

420 |

33 |

10-20 |

3800 |

60 |

|

UCE-UT-4060 PZT-8 |

55 |

300 |

40 |

10-20 |

3800 |

60 |

|

UCE-UT-4060 PZT-4 |

56 |

310 |

40 |

10-20 |

5400 |

60 |

|

UCE-UT-4050 PZT-4 |

54 |

260 |

40 |

10-20 |

4100 |

50 |

|

UCE-UT-4050-1 PZT-4 |

57 |

300 |

40 |

10-20 |

4100 |

50 |

|

UCE-UT-5435 PZT-4 |

36 |

135 |

54 |

10-20 |

3200 |

35 |

|

UCE-UT-6860 PZT-8 |

80 |

460 |

68 |

10-20 |

3800 |

60 |

|

UCE-UT-68120 PZT-4 |

67 |

588 |

68 |

10-20 |

7800 |

120 |

|

UCE-UT-8060 PZT-4 |

60 |

325 |

80 |

10-20 |

5400 |

60 |

|

UCE-UT-12060 PZT-4 |

56 |

260 |

120 |

10-20 |

5400 |

60 |

|

UCE-UT-13550 PZT-4 |

54 |

215 |

135 |

10-20 |

4200 |

50 |

ultrasonic transducer for cleaning 28khz/40khz